commonly used in industrial applications. This type of motor has three main parts, rotor, stator, and enclosure. The stator and rotor do the work, and the enclosure protects the stator and rotor.

Stator Core

The stator is the stationary part of the motor’s electromagnetic circuit. The stator core is made up of many thin metal sheets, called laminations. Laminations are used to reduce energy loses that would result if a solid core were used.

Stator Windings Stator laminations are stacked together forming a hollow cylinder. Coils of insulated wire are inserted into slots of the stator core.

When the assembled motor is in operation, the stator windings are connected directly to the power source. Each grouping of coils, together with the steel core it surrounds, becomes an electromagnet when current is applied. Electromagnetism is the basic principle behind motor operation.

Rotor Construction

The rotor is the rotating part of the motor’s electromagnetic circuit. The most common type of rotor used in a three-phase induction motor is a squirrel cage rotor. Other types of rotor construction is discussed later in the course. The squirrel cage rotor is so called because its construction is reminiscent of the rotating exercise wheels found in some pet cages.

A squirrel cage rotor core is made by stacking thin steel laminations to form a cylinder.

Rather than using coils of wire as conductors, conductor bars are die cast into the slots evenly spaced around the cylinder. Most squirrel cage rotors are made by die casting aluminum to form the conductor bars. Siemens also makes motors with die cast copper rotor conductors. These motor exceed NEMA Premium efficiency standards.

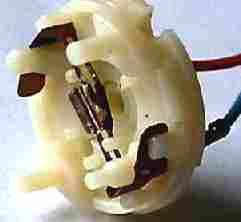

After die casting, rotor conductor bars are mechanically and electrically connected with end rings. The rotor is then pressed onto a steel shaft to form a rotor assembly.

Enclosure

The enclosure consists of a frame (or yoke) and two end brackets (or bearing housings). The stator is mounted inside the frame. The rotor fits inside the stator with a slight air gap separating it from the stator. There is no direct physical connection between the rotor and the stator.

The enclosure protects the internal parts of the motor from water and other environmental elements. The degree of protection depends upon the type of enclosure. Enclosure types are discussed later in this course.

Bearings, mounted on the shaft, support the rotor and allow it to turn. Some motors, like the one shown in the following illustration, use a fan, also mounted on the rotor shaft, to cool the motor when the shaft is rotating.

Stator Core

The stator is the stationary part of the motor’s electromagnetic circuit. The stator core is made up of many thin metal sheets, called laminations. Laminations are used to reduce energy loses that would result if a solid core were used.

Stator Windings Stator laminations are stacked together forming a hollow cylinder. Coils of insulated wire are inserted into slots of the stator core.

When the assembled motor is in operation, the stator windings are connected directly to the power source. Each grouping of coils, together with the steel core it surrounds, becomes an electromagnet when current is applied. Electromagnetism is the basic principle behind motor operation.

Rotor Construction

The rotor is the rotating part of the motor’s electromagnetic circuit. The most common type of rotor used in a three-phase induction motor is a squirrel cage rotor. Other types of rotor construction is discussed later in the course. The squirrel cage rotor is so called because its construction is reminiscent of the rotating exercise wheels found in some pet cages.

A squirrel cage rotor core is made by stacking thin steel laminations to form a cylinder.

Rather than using coils of wire as conductors, conductor bars are die cast into the slots evenly spaced around the cylinder. Most squirrel cage rotors are made by die casting aluminum to form the conductor bars. Siemens also makes motors with die cast copper rotor conductors. These motor exceed NEMA Premium efficiency standards.

After die casting, rotor conductor bars are mechanically and electrically connected with end rings. The rotor is then pressed onto a steel shaft to form a rotor assembly.

Enclosure

The enclosure consists of a frame (or yoke) and two end brackets (or bearing housings). The stator is mounted inside the frame. The rotor fits inside the stator with a slight air gap separating it from the stator. There is no direct physical connection between the rotor and the stator.

The enclosure protects the internal parts of the motor from water and other environmental elements. The degree of protection depends upon the type of enclosure. Enclosure types are discussed later in this course.

Bearings, mounted on the shaft, support the rotor and allow it to turn. Some motors, like the one shown in the following illustration, use a fan, also mounted on the rotor shaft, to cool the motor when the shaft is rotating.